PP 51-00 - TOP PUNCH PRESS - LATERAL EYES

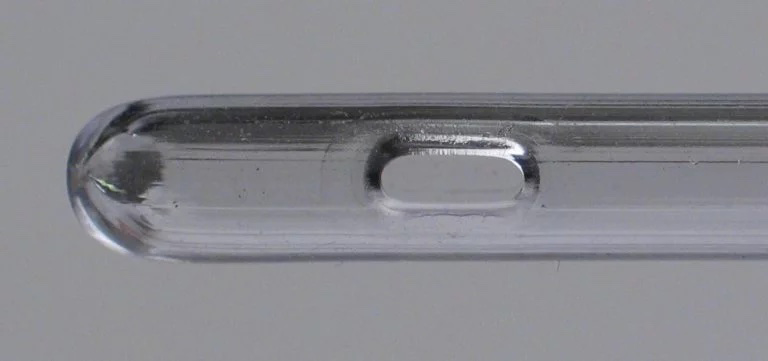

With the punching press PP 51-00, 2 top cut lateral eyes are punched in disposable medical catheters.

The soft eye forming machine is designed to punch two top cut lateral eyes and then form the outside cutting edge on the punched eyes on disposable medical catheters produced from thermoplastic material.

The PPH 61 is designed to punch two lateral eyes and form the outside cutting edge on the punched eyes on disposable medical catheters produced from thermoplastic material.

A catheter tube is manually placed and pushed to the end of the punch unit, and the punching and forming of 2 top cut eyes takes place.

The punch unit has 2 stations. Tube heating and Punching. In the first station, the tube is heated for a certain amount of time – after heating, the tube is automatic moved to second station, where the holes are punched and formed.

All forming parameters, such as time and temperatures, can be controlled from the touch Screen and different product recipes can be stored.

One of the benefits is that the punch and forming station is cold, and its only the tube that is heated.

This process can be done after the tip have been formed, an inside mandrel is not needed.

A punch waste system can be added as an option.

It is recommended to operate the machine in a clean environment.

SPECIFICATIONS

Production capacity:

The production capacity is between 600-1.000 units per hour. Depending on the CH size of the tube and the experience of the operator.

Tube specifications:

Tube Diameter: CH/Fr 6-36 (one toolset is used for each CH size and eye pattern).

Tube Material: Most thermoplastics.

Tube Length: Infinite.

.

Installation:

Power: 1x230 V AC 50-60Hz 10A.

Compressed Air: 8 bars of cleaned and dried air.

Please contact Jacob Søbygaard for more information about the eye punching and forming machine

With the punching press PP 51-00, 2 top cut lateral eyes are punched in disposable medical catheters.